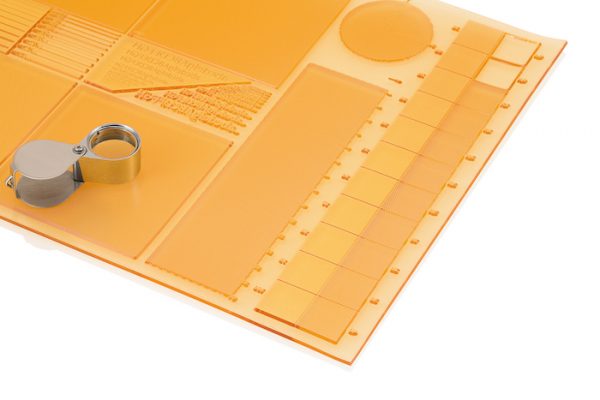

Plates used for flexographic printing are executed by the digital method known as “computer to plate”, the raw material being used by the world’s best producers: DuPont and Kodak.

HD Flexo or Flat Dot plates with new generation machines allow us to print at over 160 lpi resolutions in 8 colors on 10 to 250 μm thick material, either aluminum, polyethylene, polypropylene or paper.

Computer to plate

Plates used for flexographic printing are executed by the digital method.

High resolution

HD Flexo or Flat Dot plates allow printing resolution higher then 160 lpi

Materials

Aluminum, polyethylene, polypropylene or paper with thickness between 10 and 250 μm

Printing

Printing is done by flexography in up to 8 colors and protective lacquer.

PRINTING

Advantages of the flexographic printing process:

- a wide variety of absorbent and non-absorbent materials can be printed.

- achieving high productivity due to high print speeds.

- making high-resolution color selections (150-175lpi), which gives a high print quality, similar to offset or rotogravure technology.

- application of fluorescent and metallic inks.

- possibility of realization of the works with great draft, in very short time.

- competitive costs compared to other technologies.